-

Español

Español

-

Portugues

Portugues

-

Pусский

Pусский

-

Français

Français

-

Deutsch

Deutsch

-

日本語

日本語

-

한국어

한국어

-

العربية

العربية

-

Italiano

Italiano

-

Nederlands

Nederlands

-

Ελληνικά

Ελληνικά

-

Svenska

Svenska

-

Polski

Polski

-

ไทย

ไทย

-

Türk dili

Türk dili

-

हिन्दी

हिन्दी

-

Indonesia

Indonesia

-

Melayu

Melayu

-

Tiếng Việt

Tiếng Việt

-

中文

中文

-

dansk

dansk

-

Magyar

Magyar

-

қазақ

қазақ

-

বাংলা

বাংলা

-

עִברִית

עִברִית

-

čeština

čeština

-

Soomaali

Soomaali

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

українська

українська

-

norsk

norsk

-

Gaeilge

Gaeilge

-

беларускі

беларускі

-

Română

Română

-

ພາສາລາວ

ພາສາລາວ

-

Filipino

Filipino

-

lietuvių

lietuvių

-

Cymraeg

Cymraeg

-

македонски

македонски

-

Suomalainen

Suomalainen

-

slovenský

slovenský

-

o'zbek

o'zbek

-

اردو

اردو

-

հայերեն

հայերեն

-

Igbo

Igbo

-

български

български

-

سنڌي

سنڌي

-

Shona

Shona

-

සිංහල

සිංහල

-

Hrvatski

Hrvatski

-

íslenskur

íslenskur

-

galego

galego

-

català

català

-

Zulu South Africa

Zulu South Africa

-

Afrikaans isiXhosa

Afrikaans isiXhosa

-

ಕನ್ನಡ

ಕನ್ನಡ

-

lëtzebuergesch

lëtzebuergesch

-

Indonésia Sunda

Indonésia Sunda

-

basa jawa

basa jawa

-

ગુજરાતી

ગુજરાતી

-

Кыргызча

Кыргызча

-

тоҷикӣ

тоҷикӣ

-

Србија

Србија

-

Twi

Twi

-

Hawaii

Hawaii

-

Cebu

Cebu

-

नेपाल

नेपाल

-

euskara

euskara

-

Kurdî

Kurdî

-

frissi

frissi

-

יידיש

יידיש

-

latvija

latvija

-

slovenija

slovenija

-

kiswahili

kiswahili

-

ਪੰਜਾਬ

ਪੰਜਾਬ

-

پښتو

پښتو

-

საქართველოს

საქართველოს

-

hua moni

hua moni

-

bosna

bosna

-

తెలుగు

తెలుగు

-

தமிழ்

தமிழ்

-

Kreyòl ayisyen

Kreyòl ayisyen

-

Eesti

Eesti

-

Corsica

Corsica

-

Yoruba

Yoruba

-

Gàidhlig na h-Alba

Gàidhlig na h-Alba

-

Samoa

Samoa

-

Монгол

Монгол

-

Hausa

Hausa

-

Azərbaycan

Azərbaycan

-

አማራ

አማራ

-

Shqipëria

Shqipëria

-

Malagasy

Malagasy

-

मराठी

मराठी

-

മലയാളം

മലയാളം

-

Malta

Malta

-

ខ្មែរ

ខ្មែរ

-

Chicheva

Chicheva

-

中文(繁体)

中文(繁体)

-

ଓଡିଆ

ଓଡିଆ

-

Setswana

Setswana

-

Afrikaans

Afrikaans

-

Aymara

Aymara

-

Башҡорт

Башҡорт

-

Türkmenler

Türkmenler

-

ትግሪኛ

ትግሪኛ

-

Afaan Oromoo

Afaan Oromoo

-

অসমীয়া

অসমীয়া

-

Kinyarwanda

Kinyarwanda

-

Ilocano

Ilocano

-

Wolof

Wolof

-

अवधी

अवधी

-

Oluganda

Oluganda

-

Bikol

Bikol

-

Fulɓe

Fulɓe

-

Kikongo

Kikongo

-

Sango

Sango

-

ދިވެހި

ދިވެހި

-

Lingala

Lingala

-

मैथिली

मैथिली

-

Tsonga

Tsonga

-

ꯃꯦꯏ ꯊꯥꯏ꯫

ꯃꯦꯏ ꯊꯥꯏ꯫

-

brezhoneg

brezhoneg

-

Furlan

Furlan

-

नेवा

नेवा

-

རྫོང་ཁ

རྫོང་ཁ

-

Santali

Santali

-

Аҧсуа

Аҧсуа

-

Нохчийн

Нохчийн

-

Чӑваш

Чӑваш

-

Татар

Татар

-

Batak Karo

Batak Karo

-

دری

دری

-

Diura

Diura

-

Fengyu

Fengyu

-

Eʋegbe

Eʋegbe

-

Iban

Iban

-

Fiji

Fiji

-

Tonga

Tonga

-

Inuktitut

Inuktitut

-

Nahuatl

Nahuatl

-

maaya yucatec

maaya yucatec

-

Runasimi

Runasimi

-

guarani

guarani

-

Qafar

Qafar

-

Acholi

Acholi

-

Dinka

Dinka

-

Luo

Luo

-

Lundi

Lundi

-

isiNdebele

isiNdebele

-

Tshivenḓa

Tshivenḓa

-

Sesotho sa Leboa

Sesotho sa Leboa

-

Sesotho sa Borwa

Sesotho sa Borwa

-

Ndumbe

Ndumbe

-

Papuan Pidgin

Papuan Pidgin

-

Rromani ćhib

Rromani ćhib

-

Thok Nath

Thok Nath

yuxiatugong@163.com

+86 18353494641

-

Español

Español

-

Portugues

Portugues

-

Pусский

Pусский

-

Français

Français

-

Deutsch

Deutsch

-

日本語

日本語

-

한국어

한국어

-

العربية

العربية

-

Italiano

Italiano

-

Nederlands

Nederlands

-

Ελληνικά

Ελληνικά

-

Svenska

Svenska

-

Polski

Polski

-

ไทย

ไทย

-

Türk dili

Türk dili

-

हिन्दी

हिन्दी

-

Indonesia

Indonesia

-

Melayu

Melayu

-

Tiếng Việt

Tiếng Việt

-

中文

中文

-

dansk

dansk

-

Magyar

Magyar

-

қазақ

қазақ

-

বাংলা

বাংলা

-

עִברִית

עִברִית

-

čeština

čeština

-

Soomaali

Soomaali

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

українська

українська

-

norsk

norsk

-

Gaeilge

Gaeilge

-

беларускі

беларускі

-

Română

Română

-

ພາສາລາວ

ພາສາລາວ

-

Filipino

Filipino

-

lietuvių

lietuvių

-

Cymraeg

Cymraeg

-

македонски

македонски

-

Suomalainen

Suomalainen

-

slovenský

slovenský

-

o'zbek

o'zbek

-

اردو

اردو

-

հայերեն

հայերեն

-

Igbo

Igbo

-

български

български

-

سنڌي

سنڌي

-

Shona

Shona

-

සිංහල

සිංහල

-

Hrvatski

Hrvatski

-

íslenskur

íslenskur

-

galego

galego

-

català

català

-

Zulu South Africa

Zulu South Africa

-

Afrikaans isiXhosa

Afrikaans isiXhosa

-

ಕನ್ನಡ

ಕನ್ನಡ

-

lëtzebuergesch

lëtzebuergesch

-

Indonésia Sunda

Indonésia Sunda

-

basa jawa

basa jawa

-

ગુજરાતી

ગુજરાતી

-

Кыргызча

Кыргызча

-

тоҷикӣ

тоҷикӣ

-

Србија

Србија

-

Twi

Twi

-

Hawaii

Hawaii

-

Cebu

Cebu

-

नेपाल

नेपाल

-

euskara

euskara

-

Kurdî

Kurdî

-

frissi

frissi

-

יידיש

יידיש

-

latvija

latvija

-

slovenija

slovenija

-

kiswahili

kiswahili

-

ਪੰਜਾਬ

ਪੰਜਾਬ

-

پښتو

پښتو

-

საქართველოს

საქართველოს

-

hua moni

hua moni

-

bosna

bosna

-

తెలుగు

తెలుగు

-

தமிழ்

தமிழ்

-

Kreyòl ayisyen

Kreyòl ayisyen

-

Eesti

Eesti

-

Corsica

Corsica

-

Yoruba

Yoruba

-

Gàidhlig na h-Alba

Gàidhlig na h-Alba

-

Samoa

Samoa

-

Монгол

Монгол

-

Hausa

Hausa

-

Azərbaycan

Azərbaycan

-

አማራ

አማራ

-

Shqipëria

Shqipëria

-

Malagasy

Malagasy

-

मराठी

मराठी

-

മലയാളം

മലയാളം

-

Malta

Malta

-

ខ្មែរ

ខ្មែរ

-

Chicheva

Chicheva

-

中文(繁体)

中文(繁体)

-

ଓଡିଆ

ଓଡିଆ

-

Setswana

Setswana

-

Afrikaans

Afrikaans

-

Aymara

Aymara

-

Башҡорт

Башҡорт

-

Türkmenler

Türkmenler

-

ትግሪኛ

ትግሪኛ

-

Afaan Oromoo

Afaan Oromoo

-

অসমীয়া

অসমীয়া

-

Kinyarwanda

Kinyarwanda

-

Ilocano

Ilocano

-

Wolof

Wolof

-

अवधी

अवधी

-

Oluganda

Oluganda

-

Bikol

Bikol

-

Fulɓe

Fulɓe

-

Kikongo

Kikongo

-

Sango

Sango

-

ދިވެހި

ދިވެހި

-

Lingala

Lingala

-

मैथिली

मैथिली

-

Tsonga

Tsonga

-

ꯃꯦꯏ ꯊꯥꯏ꯫

ꯃꯦꯏ ꯊꯥꯏ꯫

-

brezhoneg

brezhoneg

-

Furlan

Furlan

-

नेवा

नेवा

-

རྫོང་ཁ

རྫོང་ཁ

-

Santali

Santali

-

Аҧсуа

Аҧсуа

-

Нохчийн

Нохчийн

-

Чӑваш

Чӑваш

-

Татар

Татар

-

Batak Karo

Batak Karo

-

دری

دری

-

Diura

Diura

-

Fengyu

Fengyu

-

Eʋegbe

Eʋegbe

-

Iban

Iban

-

Fiji

Fiji

-

Tonga

Tonga

-

Inuktitut

Inuktitut

-

Nahuatl

Nahuatl

-

maaya yucatec

maaya yucatec

-

Runasimi

Runasimi

-

guarani

guarani

-

Qafar

Qafar

-

Acholi

Acholi

-

Dinka

Dinka

-

Luo

Luo

-

Lundi

Lundi

-

isiNdebele

isiNdebele

-

Tshivenḓa

Tshivenḓa

-

Sesotho sa Leboa

Sesotho sa Leboa

-

Sesotho sa Borwa

Sesotho sa Borwa

-

Ndumbe

Ndumbe

-

Papuan Pidgin

Papuan Pidgin

-

Rromani ćhib

Rromani ćhib

-

Thok Nath

Thok Nath

News Center

News Center

HOT PRODUCT

Swimming Pool Waterproof Sheet Membrane for Tile and Plaster

2025-10-12 08:09:31

Swimming Pool Waterproof Sheet Membrane for Tile and Plaster: A Comprehensive Guide

Introduction

Swimming pools are complex structures that require meticulous waterproofing to ensure durability, safety, and longevity. One of the most critical components in pool construction is the waterproof sheet membrane, which acts as a barrier against water penetration, preventing leaks and structural damage. This guide explores the importance of waterproof membranes for tiled and plastered swimming pools, their types, installation methods, and best practices for ensuring a watertight and long-lasting pool structure.

1. Importance of Waterproofing in Swimming Pools

Waterproofing is essential in swimming pools for several reasons:

- Prevents Water Leakage: Without proper waterproofing, water can seep into the pool’s structure, leading to cracks, corrosion, and structural failure.

- Protects Against Chemical Damage: Pool water contains chlorine and other chemicals that can degrade concrete and plaster over time. A waterproof membrane acts as a protective layer.

- Prevents Mold and Algae Growth: Moisture penetration can lead to mold and algae growth, which is unsightly and can pose health risks.

- Enhances Durability: A well-installed waterproof membrane extends the lifespan of the pool by preventing water-induced deterioration.

2. Types of Waterproof Sheet Membranes for Swimming Pools

Several types of waterproof membranes are used in swimming pool construction, each with unique properties and applications.

2.1. Liquid-Applied Membranes

Liquid membranes are applied as a coating that cures to form a seamless, flexible waterproof barrier. Common types include:

- Polyurethane-Based Membranes: Highly flexible and resistant to chemicals, making them ideal for pools.

- Acrylic-Based Membranes: Easier to apply but less durable than polyurethane.

- Epoxy Coatings: Provide excellent adhesion and chemical resistance but are less flexible.

2.2. Sheet Membranes

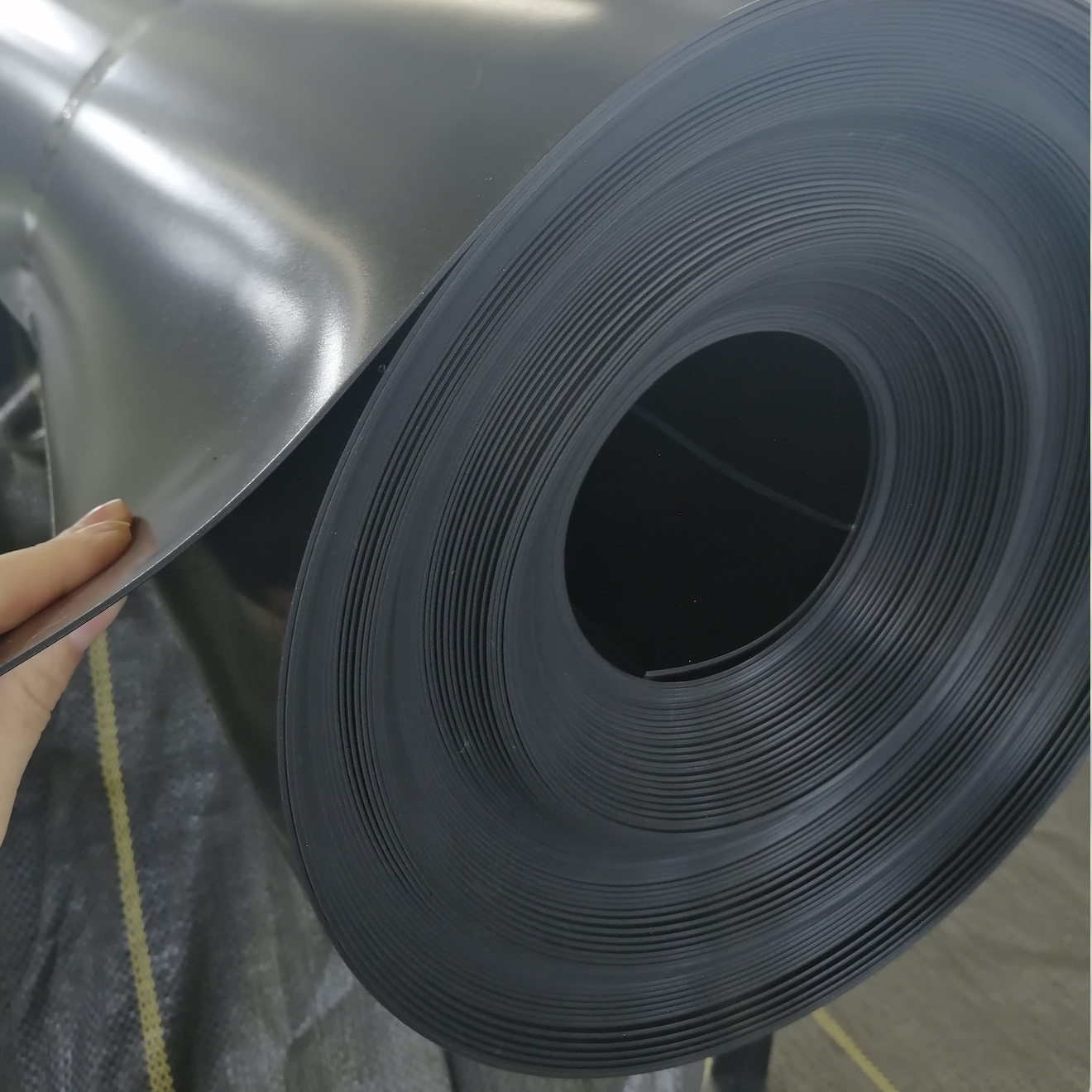

Sheet membranes are pre-fabricated waterproof layers that are adhered to the pool’s surface. They include:

- PVC (Polyvinyl Chloride) Membranes: Durable, flexible, and resistant to chemicals. Often used in commercial pools.

- EPDM (Ethylene Propylene Diene Monomer) Membranes: Highly elastic and UV-resistant, suitable for outdoor pools.

- TPO (Thermoplastic Polyolefin) Membranes: Lightweight and resistant to punctures, commonly used in modern pool construction.

2.3. Cementitious Waterproofing

Cement-based waterproofing is applied as a slurry and forms a rigid, water-resistant layer. While effective, it lacks flexibility and is often used in combination with other membranes.

3. Choosing the Right Waterproof Membrane for Tiled and Plastered Pools

The choice of waterproof membrane depends on factors such as pool design, climate, and budget.

3.1. For Tiled Pools

- Flexibility: Tiles can crack due to movement, so a flexible membrane (e.g., PVC or liquid polyurethane) is recommended.

- Adhesion: The membrane must bond well with both the substrate and tile adhesive.

- Chemical Resistance: Must withstand pool chemicals to prevent degradation.

3.2. For Plastered Pools

- Seamless Application: Liquid membranes are ideal as they form a continuous layer without joints.

- Compatibility with Plaster: The membrane should not react with plaster materials.

- Durability: Must resist abrasion from pool cleaning and maintenance.

4. Installation Process of Waterproof Sheet Membranes

Proper installation is crucial for the effectiveness of the waterproof membrane. Below is a step-by-step guide:

4.1. Surface Preparation

- Clean the substrate to remove dust, grease, and loose particles.

- Repair cracks and uneven surfaces with appropriate fillers.

- Ensure the surface is dry before applying the membrane.

4.2. Priming (If Required)

- Some membranes require a primer to enhance adhesion.

- Apply the primer evenly and allow it to dry as per manufacturer instructions.

4.3. Applying the Membrane

- For Sheet Membranes:

- Unroll the membrane and cut to fit the pool’s dimensions.

- Apply adhesive and press the membrane firmly onto the substrate.

- Seal seams with waterproof tape or welding (for PVC membranes).

- For Liquid Membranes:

- Apply using a roller, brush, or spray equipment.

- Ensure even thickness and multiple coats if necessary.

4.4. Curing and Testing

- Allow the membrane to cure fully before proceeding with tiling or plastering.

- Conduct a water test to check for leaks by filling the pool and monitoring for water loss.

5. Common Mistakes and How to Avoid Them

- Improper Surface Preparation: Skipping cleaning or repairs can lead to poor adhesion. Always ensure a clean, smooth surface.

- Incorrect Membrane Selection: Using a non-flexible membrane for tiled pools can cause cracks. Choose a product suited for the application.

- Poor Seam Sealing: In sheet membranes, improperly sealed joints can leak. Use recommended sealing techniques.

- Inadequate Curing Time: Rushing the curing process can weaken the membrane. Follow manufacturer guidelines.

6. Maintenance and Longevity of Waterproof Membranes

To maximize the lifespan of a waterproof membrane:

- Regular Inspections: Check for cracks, blisters, or signs of wear.

- Prompt Repairs: Address minor damages before they escalate.

- Avoid Harsh Cleaning Methods: Use soft brushes and non-abrasive cleaners to prevent membrane damage.

7. Conclusion

A high-quality waterproof sheet membrane is essential for the structural integrity and longevity of swimming pools, whether tiled or plastered. By selecting the right membrane, following proper installation techniques, and maintaining the waterproofing system, pool owners can ensure a leak-free and durable swimming environment. Investing in professional-grade waterproofing solutions will save costs in the long run by preventing costly repairs and extending the pool’s lifespan.

This guide provides a comprehensive overview of swimming pool waterproofing, helping contractors and homeowners make informed decisions for their pool projects.

Phone

Phone

Comment

(0)