-

Español

Español

-

Portugues

Portugues

-

Pусский

Pусский

-

Français

Français

-

Deutsch

Deutsch

-

日本語

日本語

-

한국어

한국어

-

العربية

العربية

-

Italiano

Italiano

-

Nederlands

Nederlands

-

Ελληνικά

Ελληνικά

-

Svenska

Svenska

-

Polski

Polski

-

ไทย

ไทย

-

Türk dili

Türk dili

-

हिन्दी

हिन्दी

-

Indonesia

Indonesia

-

Melayu

Melayu

-

Tiếng Việt

Tiếng Việt

-

中文

中文

-

dansk

dansk

-

Magyar

Magyar

-

қазақ

қазақ

-

বাংলা

বাংলা

-

עִברִית

עִברִית

-

čeština

čeština

-

Soomaali

Soomaali

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

українська

українська

-

norsk

norsk

-

Gaeilge

Gaeilge

-

беларускі

беларускі

-

Română

Română

-

ພາສາລາວ

ພາສາລາວ

-

Filipino

Filipino

-

lietuvių

lietuvių

-

Cymraeg

Cymraeg

-

македонски

македонски

-

Suomalainen

Suomalainen

-

slovenský

slovenský

-

o'zbek

o'zbek

-

اردو

اردو

-

հայերեն

հայերեն

-

Igbo

Igbo

-

български

български

-

سنڌي

سنڌي

-

Shona

Shona

-

සිංහල

සිංහල

-

Hrvatski

Hrvatski

-

íslenskur

íslenskur

-

galego

galego

-

català

català

-

Zulu South Africa

Zulu South Africa

-

Afrikaans isiXhosa

Afrikaans isiXhosa

-

ಕನ್ನಡ

ಕನ್ನಡ

-

lëtzebuergesch

lëtzebuergesch

-

Indonésia Sunda

Indonésia Sunda

-

basa jawa

basa jawa

-

ગુજરાતી

ગુજરાતી

-

Кыргызча

Кыргызча

-

тоҷикӣ

тоҷикӣ

-

Србија

Србија

-

Twi

Twi

-

Hawaii

Hawaii

-

Cebu

Cebu

-

नेपाल

नेपाल

-

euskara

euskara

-

Kurdî

Kurdî

-

frissi

frissi

-

יידיש

יידיש

-

latvija

latvija

-

slovenija

slovenija

-

kiswahili

kiswahili

-

ਪੰਜਾਬ

ਪੰਜਾਬ

-

پښتو

پښتو

-

საქართველოს

საქართველოს

-

hua moni

hua moni

-

bosna

bosna

-

తెలుగు

తెలుగు

-

தமிழ்

தமிழ்

-

Kreyòl ayisyen

Kreyòl ayisyen

-

Eesti

Eesti

-

Corsica

Corsica

-

Yoruba

Yoruba

-

Gàidhlig na h-Alba

Gàidhlig na h-Alba

-

Samoa

Samoa

-

Монгол

Монгол

-

Hausa

Hausa

-

Azərbaycan

Azərbaycan

-

አማራ

አማራ

-

Shqipëria

Shqipëria

-

Malagasy

Malagasy

-

मराठी

मराठी

-

മലയാളം

മലയാളം

-

Malta

Malta

-

ខ្មែរ

ខ្មែរ

-

Chicheva

Chicheva

-

中文(繁体)

中文(繁体)

-

ଓଡିଆ

ଓଡିଆ

-

Setswana

Setswana

-

Afrikaans

Afrikaans

-

Aymara

Aymara

-

Башҡорт

Башҡорт

-

Türkmenler

Türkmenler

-

ትግሪኛ

ትግሪኛ

-

Afaan Oromoo

Afaan Oromoo

-

অসমীয়া

অসমীয়া

-

Kinyarwanda

Kinyarwanda

-

Ilocano

Ilocano

-

Wolof

Wolof

-

अवधी

अवधी

-

Oluganda

Oluganda

-

Bikol

Bikol

-

Fulɓe

Fulɓe

-

Kikongo

Kikongo

-

Sango

Sango

-

ދިވެހި

ދިވެހި

-

Lingala

Lingala

-

मैथिली

मैथिली

-

Tsonga

Tsonga

-

ꯃꯦꯏ ꯊꯥꯏ꯫

ꯃꯦꯏ ꯊꯥꯏ꯫

-

brezhoneg

brezhoneg

-

Furlan

Furlan

-

नेवा

नेवा

-

རྫོང་ཁ

རྫོང་ཁ

-

Santali

Santali

-

Аҧсуа

Аҧсуа

-

Нохчийн

Нохчийн

-

Чӑваш

Чӑваш

-

Татар

Татар

-

Batak Karo

Batak Karo

-

دری

دری

-

Diura

Diura

-

Fengyu

Fengyu

-

Eʋegbe

Eʋegbe

-

Iban

Iban

-

Fiji

Fiji

-

Tonga

Tonga

-

Inuktitut

Inuktitut

-

Nahuatl

Nahuatl

-

maaya yucatec

maaya yucatec

-

Runasimi

Runasimi

-

guarani

guarani

-

Qafar

Qafar

-

Acholi

Acholi

-

Dinka

Dinka

-

Luo

Luo

-

Lundi

Lundi

-

isiNdebele

isiNdebele

-

Tshivenḓa

Tshivenḓa

-

Sesotho sa Leboa

Sesotho sa Leboa

-

Sesotho sa Borwa

Sesotho sa Borwa

-

Ndumbe

Ndumbe

-

Papuan Pidgin

Papuan Pidgin

-

Rromani ćhib

Rromani ćhib

-

Thok Nath

Thok Nath

yuxiatugong@163.com

+86 18353494641

-

Español

Español

-

Portugues

Portugues

-

Pусский

Pусский

-

Français

Français

-

Deutsch

Deutsch

-

日本語

日本語

-

한국어

한국어

-

العربية

العربية

-

Italiano

Italiano

-

Nederlands

Nederlands

-

Ελληνικά

Ελληνικά

-

Svenska

Svenska

-

Polski

Polski

-

ไทย

ไทย

-

Türk dili

Türk dili

-

हिन्दी

हिन्दी

-

Indonesia

Indonesia

-

Melayu

Melayu

-

Tiếng Việt

Tiếng Việt

-

中文

中文

-

dansk

dansk

-

Magyar

Magyar

-

қазақ

қазақ

-

বাংলা

বাংলা

-

עִברִית

עִברִית

-

čeština

čeština

-

Soomaali

Soomaali

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

українська

українська

-

norsk

norsk

-

Gaeilge

Gaeilge

-

беларускі

беларускі

-

Română

Română

-

ພາສາລາວ

ພາສາລາວ

-

Filipino

Filipino

-

lietuvių

lietuvių

-

Cymraeg

Cymraeg

-

македонски

македонски

-

Suomalainen

Suomalainen

-

slovenský

slovenský

-

o'zbek

o'zbek

-

اردو

اردو

-

հայերեն

հայերեն

-

Igbo

Igbo

-

български

български

-

سنڌي

سنڌي

-

Shona

Shona

-

සිංහල

සිංහල

-

Hrvatski

Hrvatski

-

íslenskur

íslenskur

-

galego

galego

-

català

català

-

Zulu South Africa

Zulu South Africa

-

Afrikaans isiXhosa

Afrikaans isiXhosa

-

ಕನ್ನಡ

ಕನ್ನಡ

-

lëtzebuergesch

lëtzebuergesch

-

Indonésia Sunda

Indonésia Sunda

-

basa jawa

basa jawa

-

ગુજરાતી

ગુજરાતી

-

Кыргызча

Кыргызча

-

тоҷикӣ

тоҷикӣ

-

Србија

Србија

-

Twi

Twi

-

Hawaii

Hawaii

-

Cebu

Cebu

-

नेपाल

नेपाल

-

euskara

euskara

-

Kurdî

Kurdî

-

frissi

frissi

-

יידיש

יידיש

-

latvija

latvija

-

slovenija

slovenija

-

kiswahili

kiswahili

-

ਪੰਜਾਬ

ਪੰਜਾਬ

-

پښتو

پښتو

-

საქართველოს

საქართველოს

-

hua moni

hua moni

-

bosna

bosna

-

తెలుగు

తెలుగు

-

தமிழ்

தமிழ்

-

Kreyòl ayisyen

Kreyòl ayisyen

-

Eesti

Eesti

-

Corsica

Corsica

-

Yoruba

Yoruba

-

Gàidhlig na h-Alba

Gàidhlig na h-Alba

-

Samoa

Samoa

-

Монгол

Монгол

-

Hausa

Hausa

-

Azərbaycan

Azərbaycan

-

አማራ

አማራ

-

Shqipëria

Shqipëria

-

Malagasy

Malagasy

-

मराठी

मराठी

-

മലയാളം

മലയാളം

-

Malta

Malta

-

ខ្មែរ

ខ្មែរ

-

Chicheva

Chicheva

-

中文(繁体)

中文(繁体)

-

ଓଡିଆ

ଓଡିଆ

-

Setswana

Setswana

-

Afrikaans

Afrikaans

-

Aymara

Aymara

-

Башҡорт

Башҡорт

-

Türkmenler

Türkmenler

-

ትግሪኛ

ትግሪኛ

-

Afaan Oromoo

Afaan Oromoo

-

অসমীয়া

অসমীয়া

-

Kinyarwanda

Kinyarwanda

-

Ilocano

Ilocano

-

Wolof

Wolof

-

अवधी

अवधी

-

Oluganda

Oluganda

-

Bikol

Bikol

-

Fulɓe

Fulɓe

-

Kikongo

Kikongo

-

Sango

Sango

-

ދިވެހި

ދިވެހި

-

Lingala

Lingala

-

मैथिली

मैथिली

-

Tsonga

Tsonga

-

ꯃꯦꯏ ꯊꯥꯏ꯫

ꯃꯦꯏ ꯊꯥꯏ꯫

-

brezhoneg

brezhoneg

-

Furlan

Furlan

-

नेवा

नेवा

-

རྫོང་ཁ

རྫོང་ཁ

-

Santali

Santali

-

Аҧсуа

Аҧсуа

-

Нохчийн

Нохчийн

-

Чӑваш

Чӑваш

-

Татар

Татар

-

Batak Karo

Batak Karo

-

دری

دری

-

Diura

Diura

-

Fengyu

Fengyu

-

Eʋegbe

Eʋegbe

-

Iban

Iban

-

Fiji

Fiji

-

Tonga

Tonga

-

Inuktitut

Inuktitut

-

Nahuatl

Nahuatl

-

maaya yucatec

maaya yucatec

-

Runasimi

Runasimi

-

guarani

guarani

-

Qafar

Qafar

-

Acholi

Acholi

-

Dinka

Dinka

-

Luo

Luo

-

Lundi

Lundi

-

isiNdebele

isiNdebele

-

Tshivenḓa

Tshivenḓa

-

Sesotho sa Leboa

Sesotho sa Leboa

-

Sesotho sa Borwa

Sesotho sa Borwa

-

Ndumbe

Ndumbe

-

Papuan Pidgin

Papuan Pidgin

-

Rromani ćhib

Rromani ćhib

-

Thok Nath

Thok Nath

News Center

News Center

HOT PRODUCT

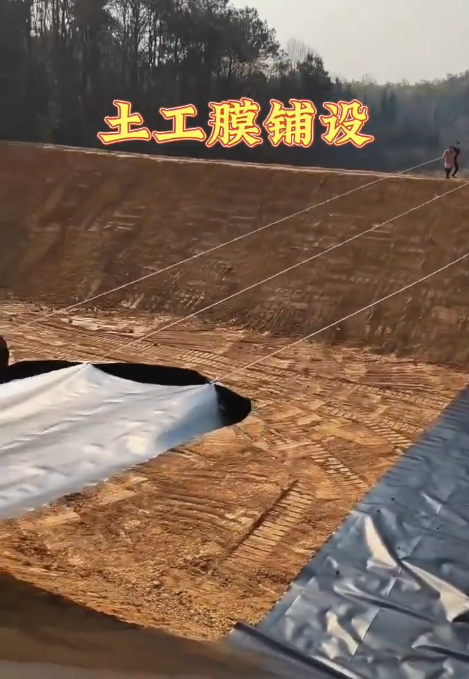

Durable Waterproof Sheet Roll Large Area Waterproofing

2025-10-20 08:19:45

Durable Waterproof Sheet Roll for Large Area Waterproofing: A Comprehensive Guide

Introduction

Waterproofing is a critical aspect of construction, renovation, and maintenance projects, ensuring the longevity and structural integrity of buildings, roofs, basements, and other surfaces exposed to moisture. Among the various waterproofing solutions available, durable waterproof sheet rolls stand out as an efficient, cost-effective, and long-lasting option for large-area applications.

This guide explores the features, benefits, installation methods, and applications of waterproof sheet rolls, providing a detailed understanding of their role in modern waterproofing systems.

---

1. Understanding Waterproof Sheet Rolls

1.1 What Are Waterproof Sheet Rolls?

Waterproof sheet rolls are flexible, high-performance membranes designed to prevent water infiltration into structures. They are manufactured from durable materials such as modified bitumen, PVC (polyvinyl chloride), TPO (thermoplastic polyolefin), EPDM (ethylene propylene diene terpolymer), and HDPE (high-density polyethylene). These sheets are available in various thicknesses, widths, and lengths to accommodate different waterproofing needs.

1.2 Key Features of High-Quality Waterproof Sheet Rolls

- Durability: Resistant to UV rays, temperature fluctuations, and mechanical stress.

- Waterproofing Efficiency: Impermeable to water, preventing leaks and moisture damage.

- Flexibility: Adapts to different surfaces, including uneven or irregular substrates.

- Chemical Resistance: Withstands exposure to harsh environmental conditions and chemicals.

- Ease of Installation: Can be mechanically fastened, adhered, or heat-welded for seamless waterproofing.

- Longevity: Provides long-term protection, often lasting 20-30 years or more.

---

2. Types of Waterproof Sheet Rolls

Different waterproof sheet rolls are designed for specific applications. The most common types include:

2.1 Bituminous Waterproofing Membranes

- Made from asphalt-modified bitumen reinforced with polyester or fiberglass.

- Ideal for roofs, foundations, and below-grade waterproofing.

- Applied via torch-on or self-adhesive methods.

2.2 PVC (Polyvinyl Chloride) Membranes

- Lightweight, flexible, and resistant to punctures.

- Suitable for roofs, tunnels, and water containment structures.

- Installed using heat welding or adhesive bonding.

2.3 TPO (Thermoplastic Polyolefin) Membranes

- Environmentally friendly, recyclable, and energy-efficient.

- Commonly used in commercial roofing due to heat-reflective properties.

- Seam welding ensures a watertight seal.

2.4 EPDM (Ethylene Propylene Diene Terpolymer) Membranes

- Highly elastic and weather-resistant.

- Used in roofing, ponds, and waterproofing decks.

- Installed via adhesive or ballasted systems.

2.5 HDPE (High-Density Polyethylene) Membranes

- Extremely durable and resistant to root penetration.

- Ideal for landfill liners, reservoirs, and underground waterproofing.

- Mechanically fastened or welded for secure installation.

---

3. Benefits of Using Waterproof Sheet Rolls for Large Areas

3.1 Superior Waterproofing Performance

Unlike liquid-applied membranes, sheet rolls provide a continuous, uniform barrier against water, reducing the risk of weak spots or application errors.

3.2 Faster Installation

Large sheets cover extensive areas quickly, reducing labor costs and project timelines compared to multiple-layer liquid coatings.

3.3 Adaptability to Various Surfaces

Waterproof sheet rolls conform to complex geometries, including curves, corners, and protrusions, ensuring complete coverage.

3.4 Minimal Maintenance

Once installed correctly, waterproof sheets require little upkeep, making them a cost-effective long-term solution.

3.5 Environmental Resistance

High-quality sheets resist UV degradation, extreme temperatures, and chemical exposure, ensuring performance in harsh climates.

---

4. Applications of Waterproof Sheet Rolls

4.1 Roofing Systems

- Flat roofs: Prevents ponding water and leaks.

- Green roofs: Protects against root penetration and moisture damage.

- Metal roofs: Provides an additional waterproofing layer.

4.2 Below-Grade Waterproofing

- Basements: Shields against groundwater infiltration.

- Tunnels and underground structures: Prevents water seepage.

4.3 Civil Engineering Projects

- Bridges and highways: Protects structural elements from water damage.

- Water reservoirs and dams: Ensures leak-proof containment.

4.4 Residential and Commercial Buildings

- Bathrooms and wet areas: Prevents mold and water damage.

- Balconies and terraces: Enhances durability against weather exposure.

4.5 Industrial Applications

- Chemical storage areas: Resists corrosive liquids.

- Parking decks: Protects against de-icing salts and water penetration.

---

5. Installation Methods for Waterproof Sheet Rolls

Proper installation is crucial for optimal performance. The most common techniques include:

5.1 Torch-On Application (Bituminous Membranes)

- The membrane is heated with a torch to melt the bitumen, creating a strong bond with the substrate.

- Requires skilled labor to avoid overheating or fire hazards.

5.2 Self-Adhesive Membranes

- Pre-coated with adhesive for easy peel-and-stick installation.

- Ideal for DIY projects and quick repairs.

5.3 Heat Welding (PVC/TPO Membranes)

- Hot air welding fuses overlapping sheets for a seamless, watertight joint.

- Ensures long-lasting waterproofing with no weak points.

5.4 Mechanical Fastening

- Sheets are secured using nails, screws, or plates, often used in roofing applications.

- Suitable for areas with high wind uplift risks.

5.5 Ballasted Installation (EPDM Roofing)

- Membranes are laid loose and held in place with gravel, pavers, or vegetation.

- Cost-effective for large flat roofs.

---

6. Maintenance and Longevity

While waterproof sheet rolls are low-maintenance, periodic inspections ensure continued effectiveness:

- Check for punctures, tears, or seam separations.

- Clear debris from roofs and drainage systems.

- Re-seal edges or penetrations if necessary.

With proper installation and care, waterproof sheet rolls can last 20-50 years, depending on material and environmental conditions.

---

7. Choosing the Right Waterproof Sheet Roll

Consider the following factors when selecting a waterproof sheet roll:

- Substrate type (concrete, wood, metal, etc.)

- Climate conditions (UV exposure, temperature extremes)

- Expected foot traffic or mechanical stress

- Budget and project requirements

Consulting with waterproofing professionals ensures the best material and installation method for your needs.

---

8. Conclusion

Durable waterproof sheet rolls offer an efficient, long-lasting solution for large-area waterproofing across residential, commercial, and industrial applications. Their versatility, ease of installation, and resistance to environmental factors make them a preferred choice for preventing water damage and enhancing structural durability.

By selecting the appropriate type of waterproof sheet roll and ensuring proper installation, property owners and contractors can achieve reliable, maintenance-free waterproofing for decades. Whether for roofing, basements, or civil engineering projects, waterproof sheet rolls provide a robust barrier against moisture, safeguarding investments and ensuring peace of mind.

Investing in high-quality waterproofing materials today prevents costly repairs tomorrow, making waterproof sheet rolls an essential component of modern construction and maintenance practices.

---

This comprehensive guide covers all aspects of durable waterproof sheet rolls, providing valuable insights for professionals and homeowners alike. If you have further questions or need assistance with waterproofing solutions, consulting an expert is always recommended.

Phone

Phone

Comment

(0)