-

Español

Español

-

Portugues

Portugues

-

Pусский

Pусский

-

Français

Français

-

Deutsch

Deutsch

-

日本語

日本語

-

한국어

한국어

-

العربية

العربية

-

Italiano

Italiano

-

Nederlands

Nederlands

-

Ελληνικά

Ελληνικά

-

Svenska

Svenska

-

Polski

Polski

-

ไทย

ไทย

-

Türk dili

Türk dili

-

हिन्दी

हिन्दी

-

Indonesia

Indonesia

-

Melayu

Melayu

-

Tiếng Việt

Tiếng Việt

-

中文

中文

-

dansk

dansk

-

Magyar

Magyar

-

қазақ

қазақ

-

বাংলা

বাংলা

-

עִברִית

עִברִית

-

čeština

čeština

-

Soomaali

Soomaali

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

українська

українська

-

norsk

norsk

-

Gaeilge

Gaeilge

-

беларускі

беларускі

-

Română

Română

-

ພາສາລາວ

ພາສາລາວ

-

Filipino

Filipino

-

lietuvių

lietuvių

-

Cymraeg

Cymraeg

-

македонски

македонски

-

Suomalainen

Suomalainen

-

slovenský

slovenský

-

o'zbek

o'zbek

-

اردو

اردو

-

հայերեն

հայերեն

-

Igbo

Igbo

-

български

български

-

سنڌي

سنڌي

-

Shona

Shona

-

සිංහල

සිංහල

-

Hrvatski

Hrvatski

-

íslenskur

íslenskur

-

galego

galego

-

català

català

-

Zulu South Africa

Zulu South Africa

-

Afrikaans isiXhosa

Afrikaans isiXhosa

-

ಕನ್ನಡ

ಕನ್ನಡ

-

lëtzebuergesch

lëtzebuergesch

-

Indonésia Sunda

Indonésia Sunda

-

basa jawa

basa jawa

-

ગુજરાતી

ગુજરાતી

-

Кыргызча

Кыргызча

-

тоҷикӣ

тоҷикӣ

-

Србија

Србија

-

Twi

Twi

-

Hawaii

Hawaii

-

Cebu

Cebu

-

नेपाल

नेपाल

-

euskara

euskara

-

Kurdî

Kurdî

-

frissi

frissi

-

יידיש

יידיש

-

latvija

latvija

-

slovenija

slovenija

-

kiswahili

kiswahili

-

ਪੰਜਾਬ

ਪੰਜਾਬ

-

پښتو

پښتو

-

საქართველოს

საქართველოს

-

hua moni

hua moni

-

bosna

bosna

-

తెలుగు

తెలుగు

-

தமிழ்

தமிழ்

-

Kreyòl ayisyen

Kreyòl ayisyen

-

Eesti

Eesti

-

Corsica

Corsica

-

Yoruba

Yoruba

-

Gàidhlig na h-Alba

Gàidhlig na h-Alba

-

Samoa

Samoa

-

Монгол

Монгол

-

Hausa

Hausa

-

Azərbaycan

Azərbaycan

-

አማራ

አማራ

-

Shqipëria

Shqipëria

-

Malagasy

Malagasy

-

मराठी

मराठी

-

മലയാളം

മലയാളം

-

Malta

Malta

-

ខ្មែរ

ខ្មែរ

-

Chicheva

Chicheva

-

中文(繁体)

中文(繁体)

-

ଓଡିଆ

ଓଡିଆ

-

Setswana

Setswana

-

Afrikaans

Afrikaans

-

Aymara

Aymara

-

Башҡорт

Башҡорт

-

Türkmenler

Türkmenler

-

ትግሪኛ

ትግሪኛ

-

Afaan Oromoo

Afaan Oromoo

-

অসমীয়া

অসমীয়া

-

Kinyarwanda

Kinyarwanda

-

Ilocano

Ilocano

-

Wolof

Wolof

-

अवधी

अवधी

-

Oluganda

Oluganda

-

Bikol

Bikol

-

Fulɓe

Fulɓe

-

Kikongo

Kikongo

-

Sango

Sango

-

ދިވެހި

ދިވެހި

-

Lingala

Lingala

-

मैथिली

मैथिली

-

Tsonga

Tsonga

-

ꯃꯦꯏ ꯊꯥꯏ꯫

ꯃꯦꯏ ꯊꯥꯏ꯫

-

brezhoneg

brezhoneg

-

Furlan

Furlan

-

नेवा

नेवा

-

རྫོང་ཁ

རྫོང་ཁ

-

Santali

Santali

-

Аҧсуа

Аҧсуа

-

Нохчийн

Нохчийн

-

Чӑваш

Чӑваш

-

Татар

Татар

-

Batak Karo

Batak Karo

-

دری

دری

-

Diura

Diura

-

Fengyu

Fengyu

-

Eʋegbe

Eʋegbe

-

Iban

Iban

-

Fiji

Fiji

-

Tonga

Tonga

-

Inuktitut

Inuktitut

-

Nahuatl

Nahuatl

-

maaya yucatec

maaya yucatec

-

Runasimi

Runasimi

-

guarani

guarani

-

Qafar

Qafar

-

Acholi

Acholi

-

Dinka

Dinka

-

Luo

Luo

-

Lundi

Lundi

-

isiNdebele

isiNdebele

-

Tshivenḓa

Tshivenḓa

-

Sesotho sa Leboa

Sesotho sa Leboa

-

Sesotho sa Borwa

Sesotho sa Borwa

-

Ndumbe

Ndumbe

-

Papuan Pidgin

Papuan Pidgin

-

Rromani ćhib

Rromani ćhib

-

Thok Nath

Thok Nath

yuxiatugong@163.com

+86 18353494641

-

Español

Español

-

Portugues

Portugues

-

Pусский

Pусский

-

Français

Français

-

Deutsch

Deutsch

-

日本語

日本語

-

한국어

한국어

-

العربية

العربية

-

Italiano

Italiano

-

Nederlands

Nederlands

-

Ελληνικά

Ελληνικά

-

Svenska

Svenska

-

Polski

Polski

-

ไทย

ไทย

-

Türk dili

Türk dili

-

हिन्दी

हिन्दी

-

Indonesia

Indonesia

-

Melayu

Melayu

-

Tiếng Việt

Tiếng Việt

-

中文

中文

-

dansk

dansk

-

Magyar

Magyar

-

қазақ

қазақ

-

বাংলা

বাংলা

-

עִברִית

עִברִית

-

čeština

čeština

-

Soomaali

Soomaali

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

українська

українська

-

norsk

norsk

-

Gaeilge

Gaeilge

-

беларускі

беларускі

-

Română

Română

-

ພາສາລາວ

ພາສາລາວ

-

Filipino

Filipino

-

lietuvių

lietuvių

-

Cymraeg

Cymraeg

-

македонски

македонски

-

Suomalainen

Suomalainen

-

slovenský

slovenský

-

o'zbek

o'zbek

-

اردو

اردو

-

հայերեն

հայերեն

-

Igbo

Igbo

-

български

български

-

سنڌي

سنڌي

-

Shona

Shona

-

සිංහල

සිංහල

-

Hrvatski

Hrvatski

-

íslenskur

íslenskur

-

galego

galego

-

català

català

-

Zulu South Africa

Zulu South Africa

-

Afrikaans isiXhosa

Afrikaans isiXhosa

-

ಕನ್ನಡ

ಕನ್ನಡ

-

lëtzebuergesch

lëtzebuergesch

-

Indonésia Sunda

Indonésia Sunda

-

basa jawa

basa jawa

-

ગુજરાતી

ગુજરાતી

-

Кыргызча

Кыргызча

-

тоҷикӣ

тоҷикӣ

-

Србија

Србија

-

Twi

Twi

-

Hawaii

Hawaii

-

Cebu

Cebu

-

नेपाल

नेपाल

-

euskara

euskara

-

Kurdî

Kurdî

-

frissi

frissi

-

יידיש

יידיש

-

latvija

latvija

-

slovenija

slovenija

-

kiswahili

kiswahili

-

ਪੰਜਾਬ

ਪੰਜਾਬ

-

پښتو

پښتو

-

საქართველოს

საქართველოს

-

hua moni

hua moni

-

bosna

bosna

-

తెలుగు

తెలుగు

-

தமிழ்

தமிழ்

-

Kreyòl ayisyen

Kreyòl ayisyen

-

Eesti

Eesti

-

Corsica

Corsica

-

Yoruba

Yoruba

-

Gàidhlig na h-Alba

Gàidhlig na h-Alba

-

Samoa

Samoa

-

Монгол

Монгол

-

Hausa

Hausa

-

Azərbaycan

Azərbaycan

-

አማራ

አማራ

-

Shqipëria

Shqipëria

-

Malagasy

Malagasy

-

मराठी

मराठी

-

മലയാളം

മലയാളം

-

Malta

Malta

-

ខ្មែរ

ខ្មែរ

-

Chicheva

Chicheva

-

中文(繁体)

中文(繁体)

-

ଓଡିଆ

ଓଡିଆ

-

Setswana

Setswana

-

Afrikaans

Afrikaans

-

Aymara

Aymara

-

Башҡорт

Башҡорт

-

Türkmenler

Türkmenler

-

ትግሪኛ

ትግሪኛ

-

Afaan Oromoo

Afaan Oromoo

-

অসমীয়া

অসমীয়া

-

Kinyarwanda

Kinyarwanda

-

Ilocano

Ilocano

-

Wolof

Wolof

-

अवधी

अवधी

-

Oluganda

Oluganda

-

Bikol

Bikol

-

Fulɓe

Fulɓe

-

Kikongo

Kikongo

-

Sango

Sango

-

ދިވެހި

ދިވެހި

-

Lingala

Lingala

-

मैथिली

मैथिली

-

Tsonga

Tsonga

-

ꯃꯦꯏ ꯊꯥꯏ꯫

ꯃꯦꯏ ꯊꯥꯏ꯫

-

brezhoneg

brezhoneg

-

Furlan

Furlan

-

नेवा

नेवा

-

རྫོང་ཁ

རྫོང་ཁ

-

Santali

Santali

-

Аҧсуа

Аҧсуа

-

Нохчийн

Нохчийн

-

Чӑваш

Чӑваш

-

Татар

Татар

-

Batak Karo

Batak Karo

-

دری

دری

-

Diura

Diura

-

Fengyu

Fengyu

-

Eʋegbe

Eʋegbe

-

Iban

Iban

-

Fiji

Fiji

-

Tonga

Tonga

-

Inuktitut

Inuktitut

-

Nahuatl

Nahuatl

-

maaya yucatec

maaya yucatec

-

Runasimi

Runasimi

-

guarani

guarani

-

Qafar

Qafar

-

Acholi

Acholi

-

Dinka

Dinka

-

Luo

Luo

-

Lundi

Lundi

-

isiNdebele

isiNdebele

-

Tshivenḓa

Tshivenḓa

-

Sesotho sa Leboa

Sesotho sa Leboa

-

Sesotho sa Borwa

Sesotho sa Borwa

-

Ndumbe

Ndumbe

-

Papuan Pidgin

Papuan Pidgin

-

Rromani ćhib

Rromani ćhib

-

Thok Nath

Thok Nath

News Center

News Center

HOT PRODUCT

Concrete Canvas Price Factors and Cost Analysis

2025-09-18 08:49:50

Concrete Canvas Price Factors and Cost Analysis

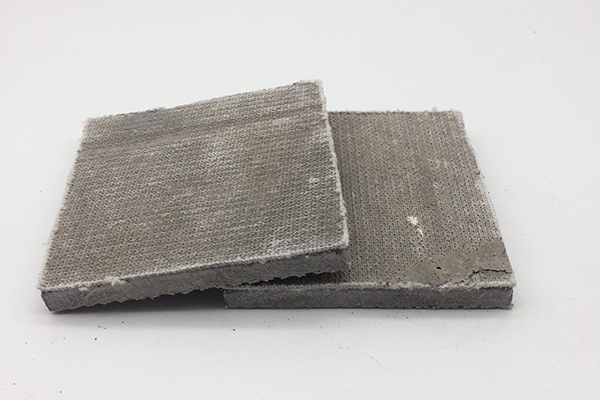

[Feature Article] – Concrete canvas, also known as cementitious geosynthetic composite mat (CGCM), is gaining global attention for its efficiency and versatility in construction. While its benefits are widely recognized, project planners and contractors often focus on the cost aspect. This article explores the main factors influencing concrete canvas pricing and provides a cost analysis to guide decision-making.

Key Price Factors

• Thickness and Grade – Thicker products such as CC13 cost more than CC5 or CC8 due to increased material usage and higher durability.

• Material Composition – Enhanced formulations with fire resistance, UV protection, or higher cement content may add to costs.

• Roll Size and Format – Bulk rolls are often more economical per square meter compared to smaller pre-cut rolls.

• Transportation and Logistics – Shipping costs vary depending on project location, roll weight, and bulk ordering quantities.

• Market Demand and Supply – Regional demand, raw material prices, and manufacturing capacity influence overall pricing.

• Certifications and Standards – Products tested and certified to international standards may carry premium prices.

Cost Analysis in Applications

• Slope Protection – Concrete canvas can reduce labor and installation costs by up to 60% compared with cast-in-place concrete.

• Channel and Ditch Lining – Faster installation and minimal equipment needs lower project budgets significantly.

• Emergency Flood Control – While unit cost may be higher, rapid deployment reduces overall emergency response expenses.

• Military Applications – Portability and ease of use reduce logistics and manpower costs in remote environments.

• Long-Term Maintenance – Durability and low repair needs ensure cost savings over the lifecycle of infrastructure projects.

Economic Benefits

• Reduced Installation Time – Projects complete faster, lowering labor costs.

• Lower Equipment Requirements – Eliminates the need for heavy machinery in many cases.

• Extended Service Life – Reduced maintenance expenses due to high durability.

• Flexibility in Procurement – Available in multiple sizes and thicknesses to balance cost and performance.

Conclusion

Concrete canvas pricing depends on factors such as thickness, composition, logistics, and certification. Although the initial investment may be higher than traditional concrete in some cases, the overall cost efficiency comes from rapid installation, reduced labor, and lower maintenance. As infrastructure projects continue to prioritize speed and sustainability, concrete canvas offers a cost-effective solution for modern engineering needs.

- Previous page: Concrete Canvas Environmental Benefits Explained

- Next page: Concrete Canvas Types and Applications Explained

Phone

Phone

Comment

(0)